Reverse Osmosis to Irrigation Water

The reverse osmosis water treatment process can turn brackish water into a valuable resource for golf courses.

by GLEN A. MILLER

WATER is perhaps the most precious resource for any golf course, and a reliable, economical supply of good quality irrigation water should be a priority for every course. What is the water situation at your course? Are you buying your irrigation water, and is the cost of water becoming a real budget issue? Do you have to curtail watering due to water restrictions? Are you located in an area where there is not sufficient fresh water to supply your irrigation needs?

Even if you are surrounded on all sides by brackish or salt water, there is an option available that can provide plenty of fresh irrigation water and save money. For golf courses in coastal areas or other areas with only brackish water available, this water can be effectively purified using the reverse osmosis (or “RO”) water treatment process.

What is Reverse Osmosis?

To understand reverse osmosis, one must first understand osmosis. Osmosis is a naturally occurring phenomenon that is all around us. The cells in your body get water via osmosis. Osmosis is the process by which water passes from a dilute (or fresh) solution to a more concentrated solution across a semipermeable membrane. The membrane is a barrier that allows the passage of water molecules, but not the passage of dissolved solids in the water.

Let’s say there are two containers, one with fresh water and the second with salty water filled to the same level and connected to the first container by a semi-permeable membrane. The natural tendency is for the two solutions to achieve the same concentration. To do this, water from the fresh side would pass to the salty side and this would continue until they reached an equilibrium. At the end, the water level on the original salty side will be higher (and now less salty), and this water height difference is called the osmotic pressure.

If we put some pressure on the salty side, it will slow down or prevent osmosis from occurring. Ifwe put more pressure on the salty side, we will not only prevent osmosis, but we will cause water to flow in the other direction, and this is called reverse osmosis.

The reverse osmosis water treatment process applies enough pressure to a salty water supply to make pure water flow through a membrane. The saltier the supply water, the higher the pressure needed to produce the water. All reverse osmosis process systems have some degree of pre-treatment needed to condition the water to minimize plugging or fouling of the membranes. Most membrane elements today can remove up to 99.5 percent of the salt from the water.

In this article, we will look at two golf courses that have built treatment systems and now make their irrigation water. We also will discuss how you can evaluate whether this option is right for your course.

The Everglades Club: Making Water and Saving 75 Percent

Located on the Barrier Island of Palm Beach on the lower southeast coast of Florida, a beautiful golf course has been maintained at the Everglades Club since the early 1920s. Surrounded by the Atlantic Ocean and the Intracoastal Waterway, the course has no fresh water and has to purchase potable water to irrigate the course. With the cost of water rising and no end in sight, the club wanted to do something to lower its water bills. In addition, the club recognized that it was using pristine drinking water for irrigation, and for environmental reasons wanted to help preserve the limited fresh groundwater. Peter Brooks, golf course superintendent for the Everglades Club, was placed in charge of finding a solution. Brooks said, “Our water bills were going through the roof. We knew we had to do something. When water restrictions came out, we knew the time to act was now.”

Miller Engineering was brought in to evaluate the situation and recommend a solution. The solution was for the club to start making its own water. Although there was no fresh water around, there was plenty of salt or brackish water. Miller Engineering designed a water plant that would use the reverse osmosis treatment process to remove the salt from the brackish groundwater and produce water fresher than they were currently buying.

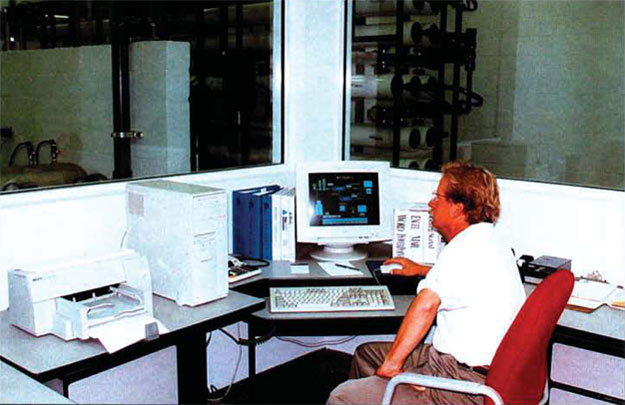

The treatment plant was designed to produce 600,000 gallons of fresh water per day. On-site shallow wells were installed to supply brackish groundwater to the plant. For every four gallons of brackish well water, the plant produces three gallons of fresh water. The treatment system is computer controlled and is designed to operate automatically. All of the equipment is housed in a building constructed on the eastern edge of the property. The only noise is the feed pump humming away on the RO system. Operators do not need to be present during plant operation, and they only need to make periodic checks to monitor the system. In fact, to save on power, which is the single largest operating cost, the system was designed to operate at night to take advantage of lower, off-peak power rates from the electric utility.

Peter Brooks has been operating the system for more than two years. Using 100 percent treated water on the golf course, operating costs to produce water are now averaging about $0.40 to $0.45 per 1,000 gallons. This cost compares to $3.18 per 1,000 gallons for potable water. With the RO system producing fresh irrigation water, the club is saving more than 75 percent of the cost previously paid to purchase water from the town. The expected payback for the irrigation water treatment system is about five years.

Jupiter Island Club: Going Deep for Savings

Kloska, golf course superintendent, recalls, “We were starting to see days when the utility company shut us down during drought conditions when we needed water the most. With more than 100 acres of golf course and landscape to irrigate, water is critical. We have a lot invested in plant material. We wanted to save money on water, which was getting expensive, but we also wanted to control our water supply and protect our investment.”

Miller Engineering evaluated the situation and recommended the most cost-effective solution. In this case, there was no shallow brackish groundwater, but there was brackish groundwater 1,500 feet down. A deep well was constructed to supply the’ brackish groundwater to a new 200,000-gallonper- day RO treatment plant (expandable to 400,000 gpd). The well was under pressure (“artesian”), which meant that a pump did not have to be placed down the well. To save payroll costs, the plant was designed to operate 24 hours per day and limited computerized operations were incorporated.

The plant has been in operation since April 1998. The treatment building was designed to be unobtrusive and is located directly on the golf course. Jim St. John, managing director, notes, “Putting the building in the middle of the course, next to the irrigation lake, made a lot of sense. We had to make sure we could hide it from view, which was not a problem.” Operating costs to produce water are comparable to the Everglades Club, and the savings are substantial. Moreover, the club now has control over the supply and quality of its irrigation water.

Is Reverse Osmosis Right for Your Course?

As cited above, you do not have to be a water treatment utility with experienced operators to consider using reverse osmosis treatment to produce irrigation water. Most systems operate automatically so that constant attention and maintenance are not required. However, several issues are important to consider in evaluating whether it will make sense to make your own water.

Water Supply

The most important thing to look at is your available water. If you have adequate fresh water from wells or other sources, treatment is not needed, and future use of this supply is not threatened, you probably don’t need to consider RO for your course. However, if you have water that is unusable because of high hardness or alkalinity, a special type of RO system termed membrane softening may be appropriate.

Reverse osmosis treatment can be performed on water with any salinity, from brackish to straight seawater. Operating costs will increase as the water salinity increases, due to the higher pressures that need to be pumped to achieve the treatment. In addition, seawater systems generally produce only 1.5 to 2.0 gallons of fresh water for every 4 gallons of feed water. Sea water generally will cost 4 to 7 times more to treat than lower-salt, brackish water. Therefore, you want to select a water supply that is plentiful and has the lowest salinity.

Permitting

RO treatment plants in Florida that are used to produce irrigation water do not require a special permit to construct. However, special permits are required to withdraw groundwater (water use permit) and to properly dispose of the unused, concentrated brine water from the system (industrial discharge permit). The water use permit is a straightforward process that normally takes three to five months to obtain.

The industrial discharge permit may take from three to nine months to obtain, depending on the individual site circumstances. It is therefore important that during the initial feasibility period, the most cost-effective brine disposal method is selected. The brine waste from the RO plant is crystal clear and poses no health threat, but environmental regulatory agencies want the disposal process permitted.

Financial Evaluation

Evaluation of the financial aspects of the RO treatment system involves an analysis of the capital costs and the operating costs. Capital costs involve the cost incurred to construct the system. These include soft costs (mainly engineering fees and permit fees) and hard costs. For an RO plant, the major hard costs are the supply wells, treatment building, brine disposal system, treatment equipment, pumps, and piping. For a typical RO plant to supply irrigation water for a golf course, capital costs will run about $1.50 to $3.00 per gallon. For a 500,000-gallon-per-day brackish water system, total capital costs will be in the $1.0 million to $1.4 million range.

Operating costs include the ongoing expenses to produce the water. These expenses include electricity, treatment chemicals, prefilter cartridges, and periodic cleaning chemicals. Normally, additional staff is not added strictly for the plant, so labor is not an operating expense. Operating expenses for brackish water systems will run $0.30 to $0.50 per 1,000 gallons produced. Electricity for a brackish plant will be about 50 percent of the total operating cost. Another recurring expense is replacement of the membrane elements in the treatment system. Elements cost about $500 to $700 each and are guaranteed for three years, but most installations can and do achieve element lives of more than 10 years. Setting aside funds for 6-year membrane replacement life will add about $0.08 per 1,000 gallons.

A payback analysis is normally performed to estimate how long it will take to repay the capital costs from the savings achieved in operating expenses versus water bills. Most brackish water irrigation plants in Florida will pay themselves back in seven to nine years.

Making irrigation water with an RO system has some substantial financial benefits for most golf courses that currently purchase irrigation water. These benefits can be more accurately estimated by performing a financial feasibility analysis during the preliminary phase of the project.

In Closing

We have presented examples of golf courses that are achieving substantial benefits by making their own irrigation water. These and other benefits can help solve your water problems. However, it is important that any golf course hire professionals experienced in completing these unique projects from start to finish. The entire process will take from 12 to 24 months from concept to producing water, and a committed team of professionals is important.